Barium Carbide

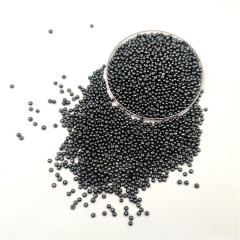

The hygroscopic chemical compound barium carbide (BaC2) is made by reacting elemental barium with carbon under high temperature. It is a member of the carbide family and has the chemical formula BaC2. It has a high specific heat, a low coefficient of expansion at elevated temperatures, and a very good electrical conductivity. It is also an excellent abrasive.

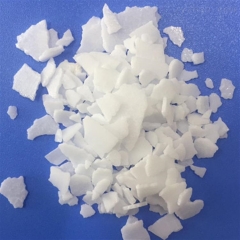

The stoichiometry of B4C is essentially pure carbon, although it may have a variable boron concentration of up to 85% of the elemental boron content. The neutron-absorption cross section of B4C is relatively constant for energies between 100 eV and 0.1 MeV, although it increases significantly above this energy range. The isotopic composition of boron in B4C is dominated by the high-cross-section isotope 10B, which contributes about 19.8% of the total boron content.

When a sufficient amount of B4C is inhaled it can cause severe lung damage, and this has been confirmed in human studies. Six of the eight patients in whom as little as 133 g of ingested barium carbonate survived, while one patient died after inhaling only 53 g.

A wide variety of carbide-carbon composites can be produced by a number of general methods, involving either direct combination of elements with carbon under high temperature or reaction of a metal compound, usually an oxide, with carbon at lower temperatures. Some of these can be prepared by hot-pressing under pressure, and others are prepared by pressureless sintering using raw or calcined coke (Processes A and B in Fig. 7-16). Plasma spraying of gaseous B4C has been used to produce a variety of composite coatings.