Sodium Silicate Production Technology and Market Prospects sodium silicate liquid manufacturers

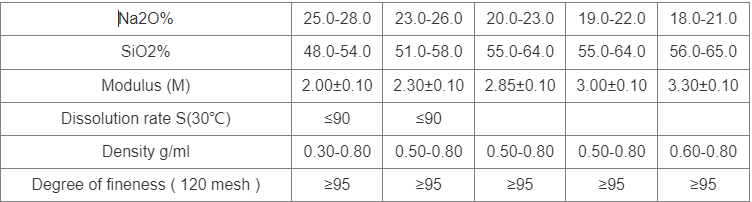

Technical Parameters of Powdered Instant Salt Silicate (CAS 1344-09-8)

(Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8))

Keep in mind: We can also customize salt silicate powder with moduli of 2.45, 2.5, and 3.4 according to your needs.

Our Variety Of Sodium Silicate Moduli

We provide powdered instant sodium silicate with moduli varying from 2.0 to 3.3. Additionally, we can personalize sodium silicate powder with moduli of 2.45, 2.5, and 3.4 to fulfill your particular needs.

Intro

Among the escalating worldwide focus on environmental preservation and lasting growth, salt silicate, a crucial not natural compound, is garnering enhanced focus across varied commercial domain names. Additionally referred to as water glass or soluble glass, salt silicate is a functional inorganic substance. It not just plays an essential duty in the construction and paper sectors however is also a vital part in detergent manufacturing. In recent years, standard phosphorus-containing cleaning agent ingredients like sodium tripolyphosphate (STPP) have been eliminated due to their extreme contamination of water bodies. Therefore, journalism demand for effective and green options has emerged. Against this background, sodium silicate has gained substantial interest as a result of its special performance benefits.

Market Potential customer

1. Global Need

The global manufacturing of artificial cleaning agents is continually expanding, with a boosting share of extremely concentrated powders. It is approximated that at least 230,000 lots of sodium silicate were required in the year 2000 alone to meet market need. Currently, the international manufacturing of sodium silicate is limited, resulting in a substantial supply-demand gap, which indicates considerable development possibility. As global customers significantly require top quality living standards, the demand for eco-friendly cleaning agents will certainly additionally rise, further driving the expansion of the sodium silicate market.

2. International Competition

Contrasted to the majority of worldwide equivalents, Chinese-produced sodium silicate not just uses a substantial rate advantage however likewise flaunts premium quality, making it very affordable for export. As an example, in the United States, the FOB cost for sodium silicate is about $51.15 per 100 extra pounds, while costs in Europe are even greater; this makes Chinese-produced sodium silicate extremely affordable in the global market. Through constant technological development and high quality enhancement, Chinese-produced salt silicate is poised to record a larger share of the global market.

Overview of Sodium Silicate

Sodium silicate is a compound created from silicon dioxide (SiO ₂) and sodium oxide (Na ₂ O), commonly stood for by the formula Na ₂ O · nSiO ₂. Relying on the worth of n, different types can be classified. Salt silicate exhibits outstanding solubility, a high pH, and exceptional cleaning buildings, making it a perfect detergent additive. Past its use in detergents, salt silicate is commonly made use of in the construction sector as a waterproofing product and sealant. In the paper market, it enhances the stamina and level of smoothness of paper. Additionally, it locates applications in fabric dyeing, oil extraction, and various other areas.

Production Process of Salt Silicate

1. Basic Material Preparation: Use water glass (or quartz sand) and caustic soft drink as base products.

2. Dissolution Phase: Blending the raw products and heating them to an ideal temperature level to advertise dissolution, guaranteeing all parts are completely mixed.

3. Formation Therapy: Controlling problems to create specific crystal structures, requiring precise law of temperature level and stress criteria.

4. Purification and Splitting up: Making use of plate and structure filters to remove excess water and pollutants, guaranteeing item pureness.

5. Drying out and Shaping: Utilizing spray drying out technology to lower the wetness web content better, ultimately forming a powdered end product, which is easy to store and transportation.

( sodium silicate)

Cost-Benefit Evaluation

1. Variable Prices: Roughly $346.71 per load, including raw materials (water glass/quartz sand + caustic soft drink), power consumption (electrical energy + gas), and labor costs.

2. Fixed Costs: Roughly $141,400 each year, covering depreciation and maintenance of set properties, monitoring costs, passion on car loans, and other expenses.

3. Overall Expenses: Considering all elements, the estimated price per lots of completed product is around $385.71.

4. Sales Revenue: With an approximated selling price of 642.86 per heap, the earnings margin is about 642.86 per bunch, theprofitmarginisabout257.15 per ton.

5. Economic Conveniences: The annual output value can get to 3,214,300, contributingapproximately3,214,300 contributingapproximately1,285,700 in tax earnings.

Conclusion

In summary, salt silicate, with its remarkable technical efficiency and lower production costs, shows great prospective in replacing typical phosphorus-containing additives. Provided the tightening environmental policies and the rising customer hunger for remarkable living requirements, the study, advancement, and commercialization of sodium silicate will undeniably serve as a vital stimulant ahead of time the international detergent sector's development. For investors, entering this field not only enhances the business's social obligation picture however also brings considerable economic returns and social benefits. As technological advancements unravel and the market broadens, the prospective applications of salt silicate are substantial and benefit extensive exploration and advancement by significant enterprises and research bodies.

High-grade Sodium Silicate distributor

TRUNNANO is a supplier of Sodium Silicate Materials with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about sodium silicate liquid manufacturers, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us [contact-form-7 id="26" title="tongrun-form"]