Introduction to Molybdenum Disulfide Pulver

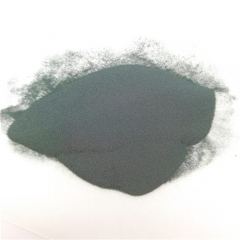

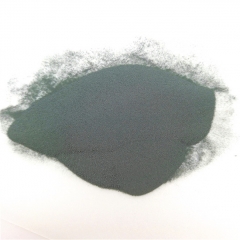

Molybdenum disulfide

is a type of inorganic. MoS2, the main ingredient of molybdenite, is its chemical formula. It is a solid black powder with a metallic luster. The melting point is 2375, the density is 4.80g/cm3(14), and Mohs Hardness is 1.0 1.5.

Molybdenum disulfide decomposes at 1370, and then to molybdenum metallic and sulfur at 1600. Molybdenum disulfide can be oxidized by heating it in air at 315. Molybdenum sulfide can't be dissolved in water, dilute or concentrated sulfuric acids. At 400, slow oxidation takes place and molybdenum dioxide forms.

Molybdenum disulfide

can be heated to produce molybdenum pythloride from chlorine gas.

Molybdenum disulfide reacts to alkyl-lipid under control to create an embedded compound (intercalated compounds) LixMoS2. If it reacts to butyllithium, then the product is LiMoS2.

Molybdenum disulfide

Copper has a high level of active sulfur. It is easy to cause copper to corrosion. This topic has been covered in many papers and books on lubricant ingredients. Additionally, when parts of copper or their alloy manufacturing require lubrication it is not necessary that lubrication products contain molybdenum disulfide. Instead, they must be combined with an anti-copper agent.

Molybdenum Disulfide Pulp Powder's Physical Chemistry

Molybdenum disulfide

It is insoluble with water and dilute acids. It can be corroded easily by concentrated sulfuric, concentrated nitric, boiling concentrated chloric acid, aqua regia or pure oxygen, fluorine, or chlorine. It is insoluble with other bases, solvents and petroleum, as well as synthetic lubricants. It is non-magnetic and has semiconductor properties. Molybdenum dioxide mo-S edges are quite numerous, easy to peel among layers, and have good anisotropy. They have strong adhesion to metal and can adhere to any metal surface. The lubricant molybdenum dioxide is high in compressive strength, wear resistance, excellent adhesion (0.03-10.08), film structures characteristics, and stable under high pressure. It can also be used under high temperatures (1200), low temperatures (-190), high speeds, high pressure, and ultra-low temperature. Molybdenum dioxide begins to oxidize at 400 to molybdenum trichloride and quickly oxidizes above 540 to molybdenum trichloride. It was sublimated to 450 in an atmosphere of inertia, then decomposed at 1370. At 1600, it was decomposed into molybdenum et sulfur. By controlled reaction of alkyl lithium and molybdenum dioxide, it was formed into molybdenum penichloride. Low toxicity.

|

Molybdenum Disulfide Powder Properties

|

|

Other names

|

Molybdenum Disulfide (Molybdenum Sulfide), MoS2

|

|

No.

|

1317-33-5

|

|

Formula compound

|

MoS2

|

|

Molecular Weight

|

160.07g/mol

|

|

Appearance

|

Solid in black/leadgray

|

|

Melting Point

|

2,375 degC (4,307 degF; 2,648 K)

|

|

Boiling Point

|

N/A

|

|

Density

|

5.06g/cm3

|

|

Solubility of H2O

|

Insoluble

|

|

Exact Mass

|

N/A

|

Molybdenum Disulfide MoS2 MoS2 powder CAS 1317-33-5

Molybdenum Disulfide Pulver Preparation Methods

Natural law

Molybdenum dioxide has many applications and great properties. Therefore, nano-mos2 preparation and application have been studied extensively at home and abroad.

MoS2 can be prepared using the natural molybdenite concentration purification method. This method removes acid insoluble matter, SiO2, Fe Cu, Cu, Ca and other impurities from molybdenite concentration after a certain physical and chemical activity and refines it to make nano-mos2. This is how the Us Climax Molybdenum firm produces MoS2. This method is suitable for the production of lubricants because it preserves the MoS2 crystal form. The natural method produces nano MoS2 with a low purity, so further refinement of the purification technology is needed. If the temperature drops below 400 degrees it is recommended that you use a low-cost MoS2 for normal conditions. It is not possible to lubricate the MoS2 with a lower lubrication level than 1300.

Chemical synthesis

The synthesis process can produce sulfide in high purity, with few impurities and fine particles, and can meet different functional requirements. This is why the synthesis procedure to make nano sulfide was so important. There are many ways to make nano-MOS2, including the thermal decomposition technique of ammonium triathiomolybdate and hydrogen sulfide reduction methods, high-energy ball grinding method, carbon nanotubes space-limiting method, hydrothermal synthesizing method, and high-energy physical or chemical means. Two preparation methods can be used to make nano-mos2: The tungsten source/molybdenum can be directly mixed with the source of sulfur, or the tungsten and molybdenum can be combined with sulfur to create the precursor body. This can then be reduced or decomposed to MoS2 with the appropriate methods.

Molybdenum Disulfide Powder - Applications

1.

Lubricants for dry films

. Molybdenum Disulfide is used in most dry film lubricants (e.g. EM-1 dry film, epoxy resin-MOS2 type), unless otherwise specified. Molybdenum-disulfide dry-film lubricants that are most commonly used are the United States military dry films MIL L-3987 and MIL L-23398. Dry film lubricant can be used to lubricate bearings, gears, and other civil products.

2.

Lubricants

. Molybdenum sulfide ointment generally is added to oil and fat with a mole fraction of about 4.4%. It has been used successfully in the fields of metallurgy and steel rolling, as well as mining machinery and equipment for coal mining. Some high temperature, open air, field, and tunnel application equipment make it difficult for grease to be lubricated or added to.

3.

Lubricating film-forming glue for wheels, rails and gear

. The film-forming powder is widely used for lubricating the gears on locomotive drive shafts, cranes or steel rolling equipment. It can also be used in large equipment like mine. You can extend the life of rail by applying film-forming paste to rail and rim. Rim life is extended 7 times and electricity or fuel is saved approximately 7%.

Main supplier of Molybdenum Disulfide Pulver

Technology Co. Ltd. is a trusted global supplier and manufacturer of chemical materials. We have more than 12 years experience in providing high-quality chemicals, nanomaterials, and zinc sulfide.

High-quality products are what you want

molybdenum disulfide granules

Please feel free and contact us to send an inquiry. (brad@ihpa.net)