Mirror stainless steel honeycomb panel ceiling, creating an excellent car buying experience 4 gang metal clad switch

Just recently, a certain brand name's 4S shop adopted mirror stainless-steel honeycomb panels as the ceiling product, intending to produce a premium automobile acquiring atmosphere. This product provides consumers with a much better experience as a result of its superb audio insulation, heat insulation, dust prevention efficiency, and visual characteristics.

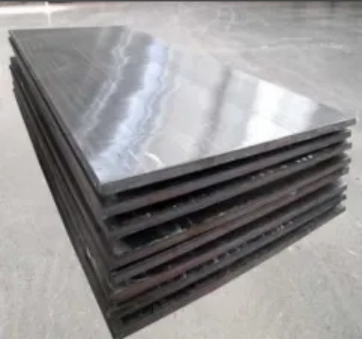

Mirror Complete Attractive Stainless Steel Plate is a specifically treated stainless steel plate with a surface area that has extremely high reflectivity and smoothness, comparable to the effect of a mirror. This product is extensively utilized in several industries due to its beauty, durability, and simplicity of maintenance.

(Mirror Finish Decorative Stainless Steel Plate)

Mirror Complete Attractive Stainless-steel Plate The advantages of using Mirror Complete Ornamental Stainless Steel Plate to mirror stainless steel honeycomb panels

High visual charm: The mirror result can make the area brighter and extra transparent, reflecting the bordering environment, and showing various colors with different scenes and lighting. The suspended ceiling that improves overall flatness and improves visual appeal not just enhances the beam of light framework, but also attains shading, appear insulation, and area enlargement, improving the visual feeling of hierarchy. In slim and reduced surge spaces, mirrors can be utilized to boost the issues of the area and aesthetically change the feeling of narrowness.

Strong load-bearing capacity: The center layer adopts an aluminum honeycomb core, which has a special structure that offers it excellent compressive efficiency while maintaining the lightweight of the product. The honeycomb structure not just guarantees the light-weight of the board, but additionally enhances it with high-strength load-bearing capacity.

Rust resistance: Stainless-steel material has excellent rust resistance and is suitable for usage in different settings.

Fire and Dampness Resistance: The fire resistance of stainless steel honeycomb panels has been accredited by the National Fire Defense Building Products High Quality Guidance Bureau, and the flame retardant performance level has reached the national A1 level fire security standard. The aluminum honeycomb core framework in the center also provides excellent moisture resistance.

High stamina and light-weight: The honeycomb framework not just makes sure the light-weight of the board, but likewise grants it with high-strength load-bearing capability. This particular allows mirror stainless steel honeycomb panels to minimize the weight of buildings and boost their security performance.

Solid durability: Stainless-steel material has excellent corrosion resistance and put on resistance, substantially prolonging the life span of put on hold ceilings.

Regarding Metalinchina

Metalcladbuilders is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality metals and metal alloy. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, Metalinchina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for 4 gang metal clad switch, please send an email to: nanotrun@yahoo.com

Inquiry us [contact-form-7 id="26" title="tongrun-form"]