What's molybdenum caride powder?

The global consumption structure can be viewed through the lens of

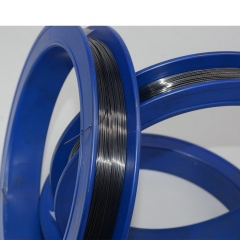

molybdenum caride Powder

Iron is actually a friend of molybdenum. The majority of molybdenum demand in Western countries comes from steel. It is 30% stainless steel and 30% low-alloy. 10% drilling and cutting tools and 10% cast steel. 20 percent of molybdenum goes into chemicals, petroleum refining and molybdenum based lubricants. In 1998, the average molybdenum consumption in American steel production was 75%. Additionally, Molybdenum based electronics, Metal processing and aerospace industry alloys are increasingly being used.

Molybdenum caride Powde:

As a coating or additive material, nanometer molybdenum carbonide is possible. You can also use it to create particle reinforced alloys. Molybdenum carbonide's electronic structure and catalytic characteristics are similar to that of noble metals. It has hydrogen denitrogenation and hydrogenolysis activity. Molybdenum is expected become an alternative to precious metals. It is also used in the manufacture of chromium free special alloys, engineering ceramics, and other materials. It serves many purposes, including hard tool material and wear resistance material. Also, it is used for heating elements and high-temperature structures. This is used in the manufacture of semiconductor films and wear-resistant film. It is also used in the manufacture of molybdenum caride. It is also used in the production of engineering ceramics and special alloys that are chromium free.

Molybdenum Carbide Pulse is Now Available in New Applications

A molybdenum disilicide mo02 (MoSi2) Mo02 is the key to solving the low elasticity problem and high oxidation problem. The molybdenum reacts with oxygen at 800, forming a complex composite. When it condenses, it forms a yellowish white cloud. This presents a major engineering challenge for those who want to take advantage of the molybdenum strengths and creep resistance. Although it is capable of self-healing, the coating is silicon-rich and has poor resistance to thermal cycling. Mo-Sii-B is a composite with Molybdenum diilicide in the matrix. It has excellent strength and resistance to oxidation, but it's limited use for small-batch products. This composite of molybdenum silica boron and molybdenum disilicide was designed to have high mechanical characteristics comparable to TZM, with excellent oxidation resistance. Mo5SiB T2 (the matrix phase) was used in the composite. The second phase consisted of metal molybdenum. This metal phase increased the strength of the composite and could also create a self healing oxide skin. Mo-6Ti2.2Si-1.1B composite was created with titanium. It was then exposed to air at 1370 degrees for 2 hours. A naked eye could not see the difference, making it superior to TZM. This is a remarkable achievement in molybdenum alloy.

Prices for molybdenum caride powder

Price of molybdenum powder will depend on the particle size and purity. The purchase volume may also have an impact on the price. Large quantities of small amounts will result in a lower price. On our official website, you can see the price for molybdenum caride Powder.

Molybdenum caride powder supplier

The Advanc3dmaterials Advanced Material Nano Technology Co. Ltd.

Luoyang City is located in Henan Province, China. This city, called "Advanc3dmaterials", has a reputation for being a trusted and reliable global supplier of chemical materials. This company is a trusted supplier of high quality chemical materials and nanotechnology products with more than 12 years experience, such as molybdenum carbonide powder, nitride Powder, graphite and sulfide Powder. We are happy to provide high quality and affordable molybdenum carbonide powder.

Get in touch

You can also inquire at any time.