Carbon Addition Effects on Zirconium Carbide Powder Rupture Strength

zirconium carbide powder is a gray metallic transition metal refractory ceramic material with excellent corrosion resistance. It is also characterized by high temperature creep resistance and good strength, hardness, and thermal conductivity.

Spark plasma sintering (SPS) is one of the most attractive rapid powder consolidation techniques and has been successfully utilized to consolidate ultra-high temperature ceramic (UHTC) materials such as tantalum carbide [1, 2], hafnium diboride, vanadium carbide, etc., into bulk articles at lower temperatures and shorter processing times compared to its conventional counterpart technique-hot pressing [3, 4].

The aim of this study was to investigate the effects of carbon addition on the transverse rupture strength of ZrC samples processed by SPS. The results indicate that the increased carbon content decreases the rupture strength. This effect is attributed to the formation of brittle phases within the sinter. In addition, the results show that stoichiometry of the ZrCx samples is not affected by the carbon content, but rather by the type of carbon present in the commercial powder used.

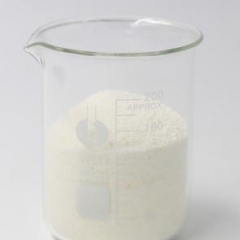

The stoichiometry of the starting commercial ZrC powder was determined by an inert gas fusion analysis using a C, N, O analyzer (EMIA 320 V2 and EMGA 820 from Horiba Scientific, Japan). The results confirmed that the original powder has a relatively high percentage of combined and free carbon species with a total carbon content of 11.6 wt%. This result is in good agreement with the stoichiometry reported for the commercial ZrC powder used.